CNC Machined Parts and Components.

CNC machining from solid, turning, and milling

Forged and Cast Components: Expertise in forged and cast parts with secondary CNC machining.

Custom Solutions: Supplying custom-machined parts from various materials, streamlining outsourcing processes for precision component manufacturing.

Complex Component Delivery: Experts in manufacturing, supplying, and delivering complex components to our customers.

Proven Track Record: Donlouco Ireland Ltd. has a successful history of supplying high-quality CNC-machined parts to customers in Ireland, the UK, and Europe.

Cost-Quality Leadership: Global leaders in providing cost-effective, high-quality solutions.

High-Volume Precision Parts and Turnkey Manufacturing Solutions.

High-Volume Precision Manufacturing

Donlouco delivers high-volume, precision hydraulic and industrial components to OEMs and manufacturers worldwide, ensuring reliable and on-time shipments, as well as consistent quality for every order.

Advanced Multi-Axis CNC Machining

Our 3, 4, and 5-axis CNC machining centres handle ferrous and non-ferrous materials, including carbon steel, stainless steel, and aluminium. Producing complex, high-tolerance parts that meet strict European standards.

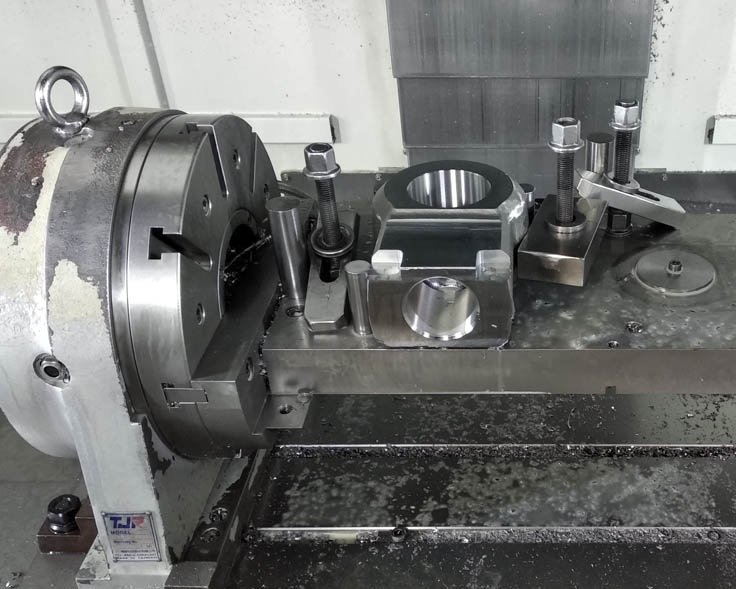

Dedicated Fixturing for Quality Consistency

Custom-designed fixturing solutions guarantee repeatable accuracy and minimise defects, supporting superior quality in high-volume production.

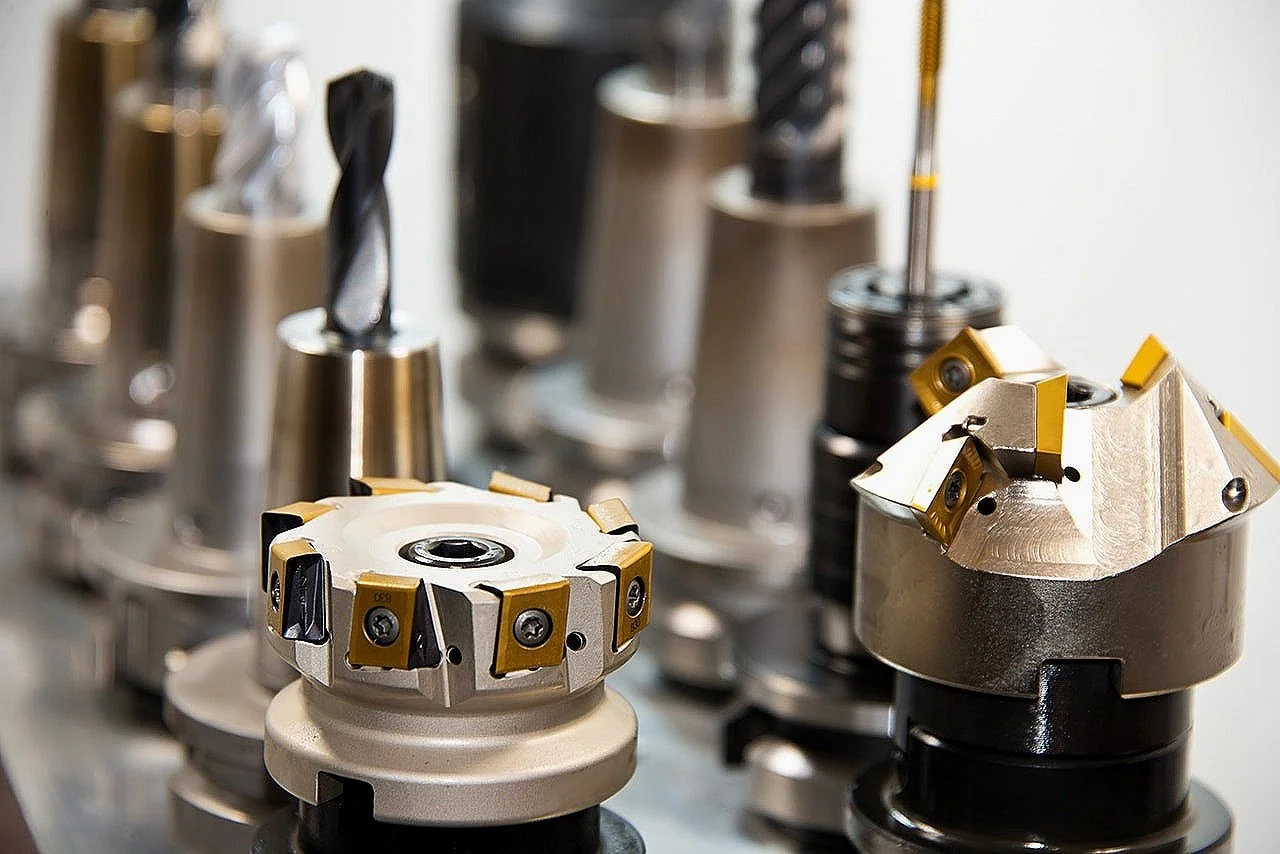

Custom Machine Tooling and Engineering

Offering customised machine tooling for customer-specific part features and standard applications. Comprehensive management of tooling design and production engineering, including hand tools, gauge tools, work holding tools (such as jigs and fixtures), and cutting tools for milling and grinding machines.

Custom CNC Machined Solutions for Hydraulic Systems.

Precision Engineering for Hydraulics

We are a supplier of components to the hydraulics industry. We have and continue to supply parts to some of the biggest manufacturers of hydraulic cylinders in Europe.

Forgings with Secondary Machining

Extensive experience in CNC machining of complex forgings, rod ends, cylinder bases and others. Multi-stage forging tool sets for high forging ratio parts.

Open hammer forging of large parts. High-grade steel manufactured to the highest possible standards and to exact customer requirements. Parts can be heat treated to customer requirements, all parts shot blasted to clean cosmetic standards.

CNC machined from solid including cylinder Pistons, Gland Nuts and Cylinder Bases with integrated ports.

Quality Assured Parts and Component Manufacturing

Highly experienced and adept in the industrial hydraulic sector, automotive, and equipment manufacturing sectors

With over 16 years of experience managing our facilities and staff in China, Donlouco is your manufacturing partner for long-term solutions.

Expert Project Management for Tooling & Complex Part Development.

Learn More About The Engineers & Managers with boots on the ground in China.

Quality CNC Machined Parts Guaranteed.

Machined To Exact Requirements

Delivering the highest possible standards of accuracy and finish to exact customer specifications. Donlouco works closely with customers to understand the intricacies of parts beyond what can be written on drawings and specifications.

A unique ability to be able to communicate these requirements to the factory floor without error.

Quality Testing

Full diagnostic capability for checking parts, CMM, Surface Measurement, Go/NoGo Gauges, and Material Analysis.

CNC Machined Parts Delivered With Full Traceability Reports etc.

Full traceability with all shipments including production data and raw material certification. Donlouco removes all of the headaches associated with distant manufacturing sites.

Engineering Capabilities To Deliver Quality Components.

Complex Machined Components

Donlouco has the expertise to manage complex components from the design stage to volume production. This includes tooling for forged and cast parts requiring secondary machining and parts requiring complex fixtures, always achieving reliable and repeatable accuracy.

Engineering Software

Donlouco can work with all standard 3D engineering software tools including CAM software to generate machine programs.

Customer-Specific Parts And Components

Donlouco also has significant experience in using custom-form tools for machining specific features in high-grade steel, stainless steel, and aluminium.

Advantages of working with Donlouco for your CNC Machining Requirements

✓ Competitive Pricing For CNC Parts.

✓ Our CNC Parts Do Not Compromise On Quality, Service Or Delivery.

✓ All CNC Machined Parts Checked Before Shipping.

✓ ISO 9001 Certified & EN1090 Certified & Approved For CE Marking Of Parts.

Competitive Pricing For CNC Machined Parts And Components.

Access To State Of The Art CNC Machining

The high upfront investment cost of CNC Machines may not be financially viable for your business. This equipment and ongoing maintenance costs can be costly to own and operate. At Donlouco, we have our own state-of-the-art CNC Machining Facility in China and employ a team of engineers who are highly skilled and experienced in operating this equipment.

Save On Overhead Costs

Outsourcing CNC Machining to Donlouco results in lower overhead costs such as labour, factory size, and holding inventory for your company.

CNC Machined Parts that Do Not Compromise On Quality.

Precision Machining Capabilities

Manufacturers that choose to outsource to Donlouco will gain access to precision parts from an experienced CNC Machining Company with the capability to consistently produce large annual volumes across a wide range of parts types and quality requirements.

Delivered on time

CNC Machined parts received from Donlouco are manufactured to your exact requirements and can be delivered using the just-in-time (JIT) system, to avoid holding inventory. Donlouco also oversees customs clearance, so you avoid any unforeseen costs.

Door-to-door service with no overhead costs to the customer.

Quality Assurance

From a manufacturing point of view, we understand the importance of receiving parts and components that are fit for purpose. Donlouco has built its brand on providing the best possible quality no matter what. Parts are plug-and-play to your manufacturing site.

Donlouco is ISO 9001 Certified and EN1090 Certified & Approved for CE Marking of Parts.

Our team of engineers and managers are dedicated to providing the best quality parts and components to meet your specific requirements.

CNC Machining, Tooling, Fixtures, Form Tools

Fixtures designed & manufactured in house by our expert CNC teams. We pride ourselves on our extensive experience with form tools for specific ports and local tool suppliers.

CNC Machining Specs

CNC Milling 3, 4 & 5 Axis

Total 18M/C

Max Part Size:

1100 x 650 x 700mm

CNC Lathe Multi Axis

Total 25M/C

Max Diameter:

1000mm, L=1M

Auto Threading M/C

Auto Threading 8M/C

Max Diameter:

120mm

CNC Machining Quality Measurement

CMM M/C

Shadowgraph

Interior/Exterior Micrometres

Vision Inspector

Hardness Tester

Vernier’s

Surface Measurement

Impact Tester

Vernier’s

CNC Machining in China.

Donlouco's Advanced Facilities in Jiashan, Shanghai

CNC Tool Shop: Selection of CNC tools for component manufacturing.

Donlouco Ireland offers a unique service with access to advanced CNC machining facilities in Jiashan, Shanghai. Our dedicated team of skilled engineers and managers are trained to European standards for precision part and component manufacturing.

Understanding Critical Component Design Needs

With extensive experience across diverse manufacturing sectors, Donlouco excels in meeting industry-specific requirements. Explore how we can assist your company in achieving competitive pricing and superior quality.

Advantages of Manufacturing in China:

High-Volume Capacity: Ability to handle large-scale manufacturing demands efficiently.

Cost Savings: Access to less expensive raw materials and lower final price-per-part costs.

Just-In-Time Logistics: Streamlined logistics to ensure timely delivery with minimal inventory holding.

Quality Assurance: Rigorous quality control systems in place to uphold high standards.