A Leading Supplier of Hydraulic Cylinder Parts.

Manufacturing to Exact Customer Requirements

All Hydraulic Cylinder Components are manufactured to the highest possible standards and to exact customer specifications. These include:

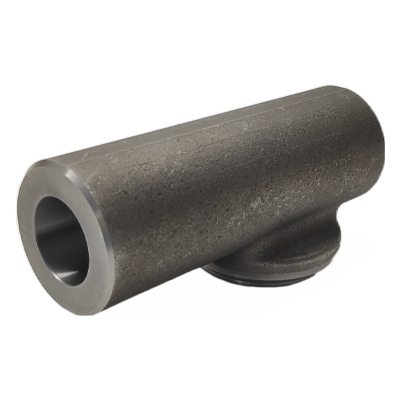

Simple Threaded Weld Ports.

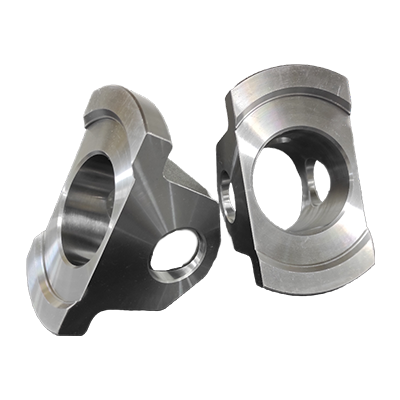

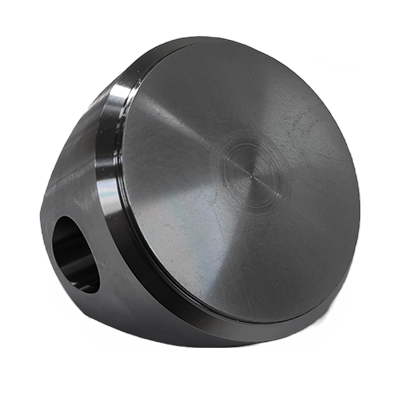

Machined Pistons.

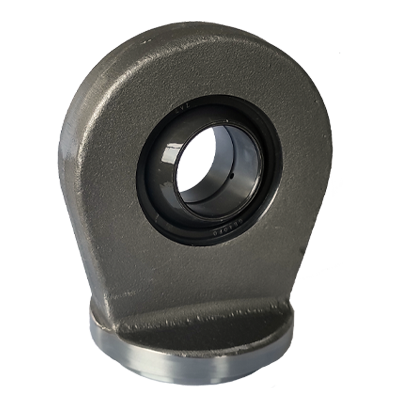

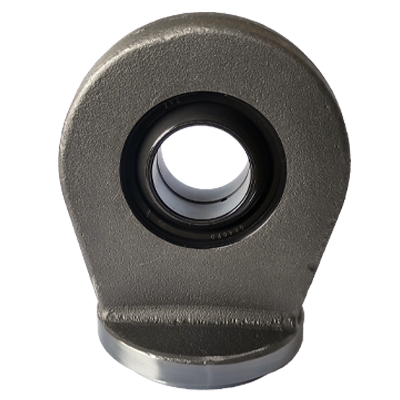

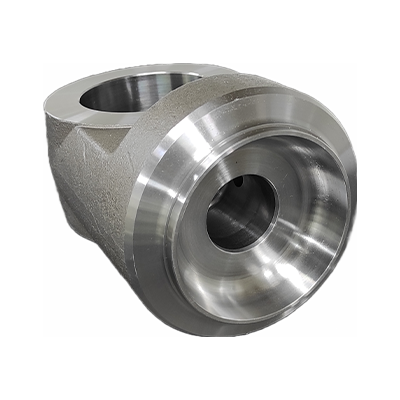

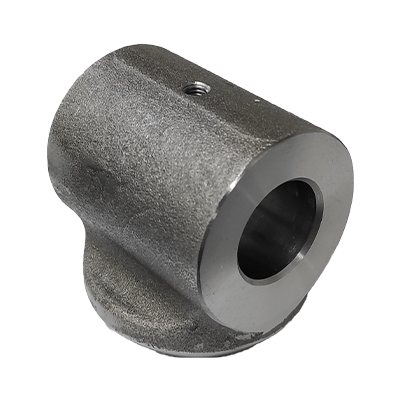

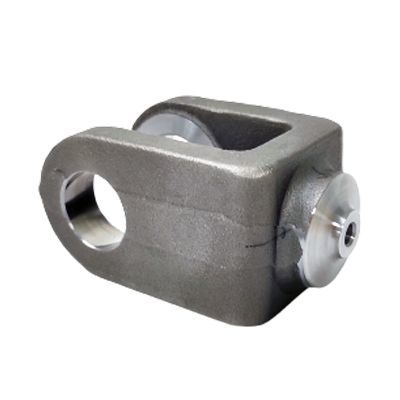

Forged Rod Ends.

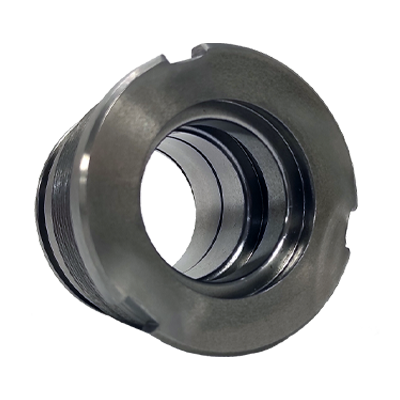

Threaded Gland Nuts and Flanges.

Forged Rod Ends and Cylinder Bases.

Quality Control & Certifications.

critical quality control

Comprehensive Testing: Tensile Testing Rod End.

Donlouco is fully ISO 9001 and EN 1090 approved for CE Marking. All staff trained to European/US standards. We prioritise critical quality and high-performance standards, utilising rigorous quality control and comprehensive testing to guarantee sustainable supply chains and long-lasting hydraulic solutions.

Experienced Manufacturing Partner

For 20 years, Donlouco has been a critical supplier of parts to hydraulic cylinder manufacturers. We have become a leading supplier of CNC-machined and forged steel parts to this industry and continue to grow with new and existing customers.

Capabilities & Manufacturing Services.

Multi-Stage Quality Checks.

efficient hydraulic component production

Donlouco delivers seamless, end-to-end manufacturing for hydraulic components, leveraging integrated supply chain management and advanced CNC technology to ensure maximum efficiency and reliability for every order.

Price-Quality Combination

Donlouco offers the best price/quality combination for hydraulic components globally.

Critical Quality and Performance

We prioritise quality and performance to ensure long-term sustainability of our supply chain.

Flexible Manufacturing Options

Benefit from highly flexible manufacturing options designed to increase capacity with minimal investment.

Reduced Overhead Costs

Achieve significant reductions in overhead costs associated with expanding capacity.

Design & Manufacture Hydraulic Cylinder Parts.

✓ Forged Cylinder Rod Ends.

✓ Forged Cylinder Bases.

✓ Ported Valve Blocks.

✓ Piston Components.

✓ Gland Nuts.

✓ Forged Couplings.

Cost-effective hydraulic parts

Tooling and Fixturing: Parts Manufactured to Exact Customer Requirements.

Donlouco sets the global standard for cost-effective hydraulic parts, combining competitive pricing with ISO 9001-certified quality to deliver unmatched value for OEMs and industrial clients.

Improved Performance

Enhanced performance resulting in long-term, reliable revenue growth.

"Plug N Play" Delivery

Parts are delivered ready to be seamlessly integrated into the manufacturing environment.

Expert Management

Donlouco’s engineers, quality control, and supply chain experts are in Ireland and the Far East.

Streamlined Service

Streamlined service, allowing customers more time and resources to focus on core value-added activities.

Enhanced Customer Experience

Improved end-customer experiences and increased sales revenue in the competitive global hydraulics market.

Dedicated Hydraulics Division.

High-Quality Forged & CNC Machined Hydraulic Cylinder Parts

Donlouco is the preferred choice for companies seeking high-quality hydraulic cylinder parts due to our unique capabilities and extensive network. Our CNC Machining Facility in Jiashan, China combined with an approved network of subcontractors for forgings and special processes, ensures the manufacture of parts to the highest standards.

Our unique ability allows us to communicate exact customer requirements far beyond what can be written on drawings and specifications all managed seamlessly from our head office here in Ireland to our experienced team of Engineers and Managers in the Far East.

Fixturing for Cylinder Parts: Forging Machined to Finish Part Level.

Precision CNC Machining for Hydraulic Components.

Donlouco specialises in precision CNC machining for hydraulic cylinder parts, offering extensive experience across a wide range of steels—including carbon steel, stainless steel, and speciality alloys. Our advanced 3, 4, and 5-axis CNC machining centres enable us to manufacture both large and small hydraulic components with complex geometries, tight tolerances (down to ±0.005mm), and superior surface finishes (Ra < 0.8μm).

We machine critical features such as valve ports and custom interfaces to meet industry standards, including SAE, T2A, JIC, Sun, and Atlantic.

Donlouco delivers consistent quality and dimensional accuracy for all hydraulic components.

Forging for Hydraulic Cylinder Parts.

Donlouco provides expert forging services for hydraulic components such as cylinder bases, flanged parts, and rod eyes. Our forging process produces hydraulic cylinder parts with superior strength and durability compared to cast or machined from solid. By optimising grain flow and material density, our forged components achieve excellent mechanical properties, critical for demanding hydraulic applications.

With forging capacities up to 1,600 tons (Die), Donlouco manufactures a broad range of part sizes and custom designs. Secondary precision CNC machining and heat treatment as required, ensuring optimal performance and longevity in service.

Extensive Hydraulics Experience.

Industry Applications.

Versatile Forging Capacity: Forging capability from small, detailed parts to large forgings of 50 kg or more.

Finished Part Production: Maximum forging capacity of 1600 Ton. Forged parts, mostly CNC machined to a finished part level.

Tool Design and Management: Forging tools are designed and managed and can be reverse-engineered from finished part drawings by Donlouco.

Steel Grades Compliance: All steel grades to meet customer requirements and European standards. Suitable steel grades are used for welded parts to ensure welding integrity is always achieved.

Comprehensive Testing: Forged parts can be fully tested, tensile, impact, etc. at the approval stage and by sampling as required.

Rigorous Quality Control: All parts are fully checked and inspected before shipping with full traceability and reports available for all shipments.

Key Advantages of for Hydraulic Cylinder Manufacturers.

✓ No Compromise In Quality, All Parts Checked Before Shipping.

✓ Capability To Precisely Communicate Requirements Directly To The Manufacturing Site.

✓ Full Traceability And Reports Available With All Shipments.

✓ Proven Track Record of Sustainable Long Term Price & Quality Service.

CNC Machining Capabilities.

3, 4 & 5 Axis CNC milling. Gantry machine.

General machining accuracy 0.005mm.

CNC Turning multi tool combination machines.

Machining of steel, cast steel or cast iron.